Heat Exchanger fryers

Heat exchanger Fryer DLNC

Allows no temperature drop at inlet

The most HIGH-END class fryer DLNC has actively working in the major processors for the last 20 years. Energy saving, stable temperature controls, higher oil turnover rate, Less oil volume, selectable heat sources are basic features of the luxurious fryer. You can choose one among various heat sources such as highpressure steam, gas and thermal oil. The flat oil pan gives a prefect environment for better hygienic cleaning. The fryer normally works in link with ADF filter which requires no consumable.

– Energy-efficient Maeda Heat Exchanger The renowned Japan Top heat exchanger generates powerful heat-transfer in high energy recovery rate.

– Paper(Screen) filter Paper filter or screen filter, depending on sediment sizes, can optionally be chosen for the outlet section.

– Non-consumable drum filter

– CCF Micro Separator This centrifugal filter works at any time, either during fryer operation or after operation, majorly for heavy specific gravity sediments (down to 1 micron).

– CO2 fire suppression system It senses fire inside fryer and immediately activates CO2 gas injection.

– Multi-point temp. control Depending on each fryer length, temperatures in multiple places such as inlet, center, outlet) are sensed for related controls.

– Sediment removal conveyors Sediments are effectively removed out of fryer during operation by the removal conveyors in inlet and outlet.

– Oil Mist Catcher minimizing critical fire accidents Food factories suffer from disputes with neighboring inhabitants and increasinglyreinforcing local environmental laws. OMC retains oil mist in water to help evading those risks. OMC furthermore keeps fire from expanding thru ducts to other working rooms.

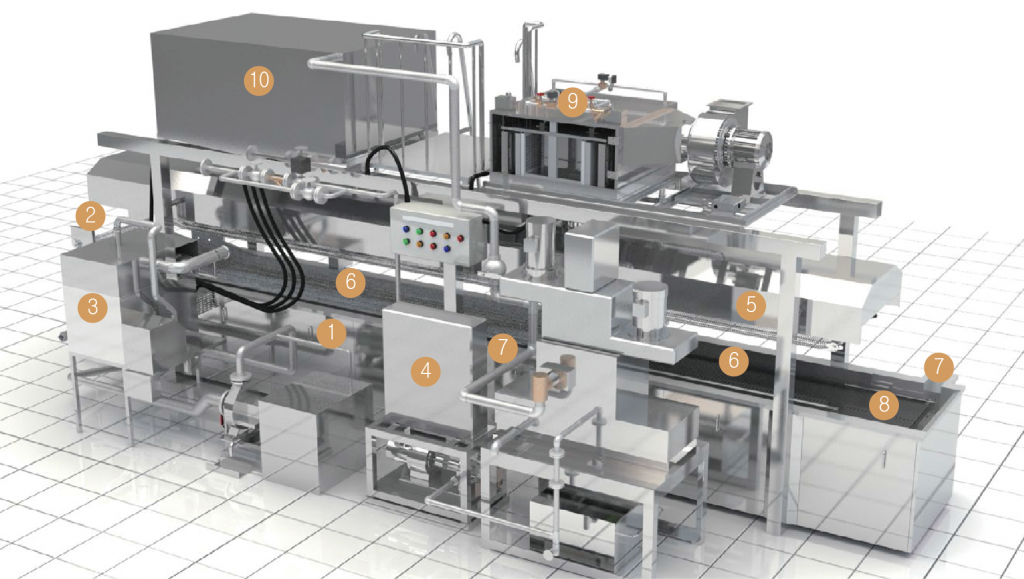

1) High output heat exchanger

2) Screen and paper filter

3) Drum filter

4) CCF micro filter (for powder)

5) CO2 fire fighter

6) 3 point temp. control

7) Sediment removals

8) Teflon infeed conveyor

9) Oil Mist Catcher

10) Oil Storage tank