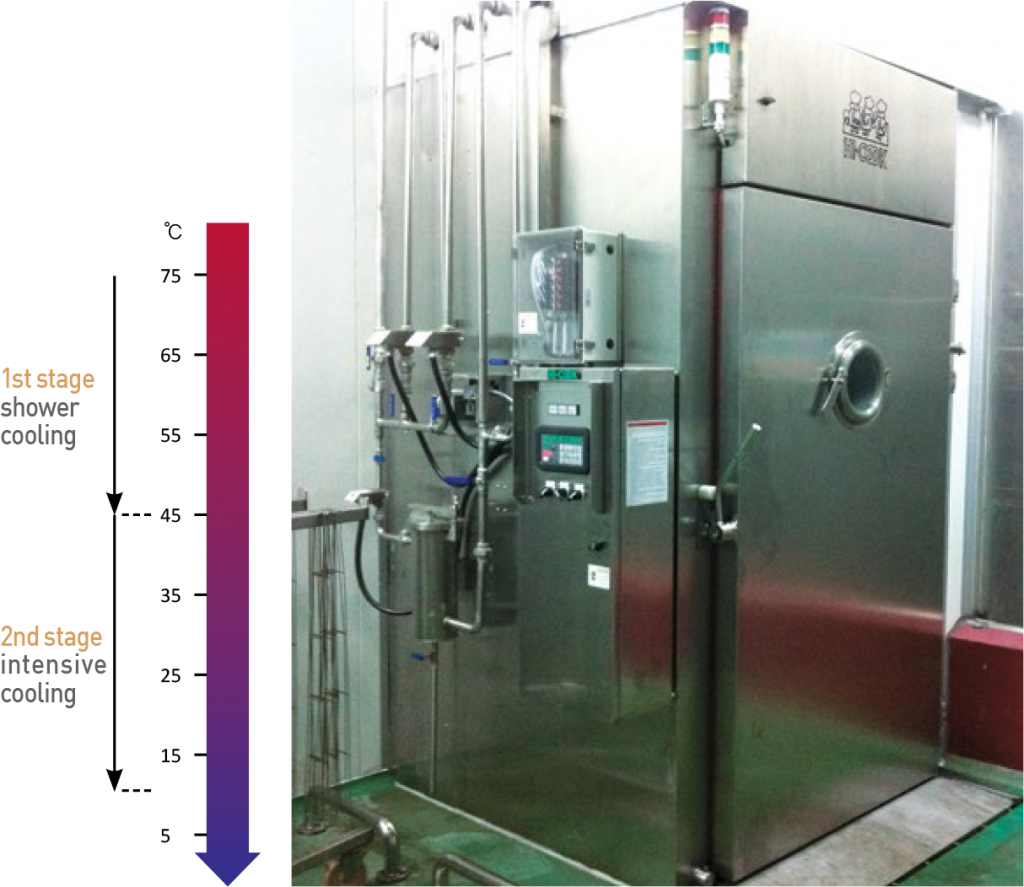

Intensive Cooler

It is not a choice, but a MUST in today’s meat processing factories. With this intensive cooler, customers can minimize bacteria risks and maximise space-efficiency. Here, cooked products can pass down thru the critical temperature zone between 50 and 15℃ in the shortest time, so the number of remaining bacteria is minimized.

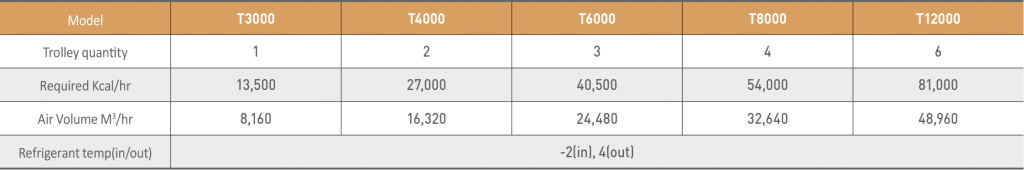

Reference

– 5.04 kg/stick (before smoking process)

– 4.71 kg/stick (after smoking process) =-6.5%

– 4.64 kg/stick (after intensive cooling ) =-1.49%

– 70℃ at core before intensive cooling

– 10℃ at core after intensive cooling